Instructions are available here

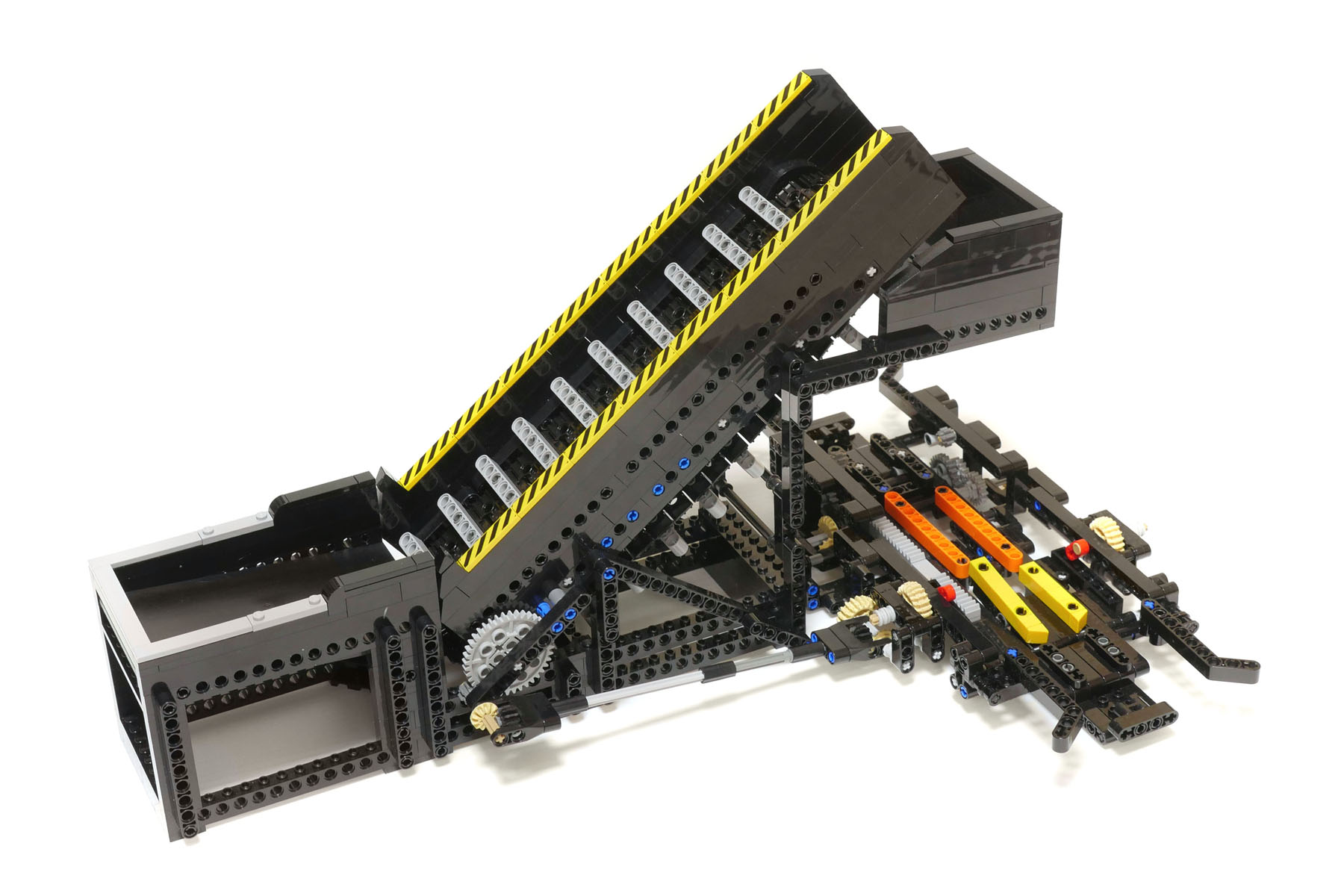

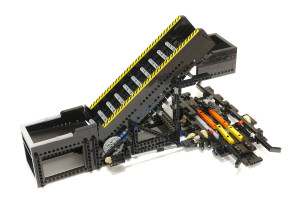

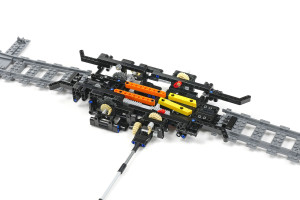

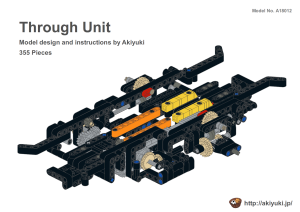

This module consists of two components, a Through Unit and a Loader Unit. A train enters and stays at the Through Unit. Then, the electric motor on the train drives the Loader Unit attached to the Through Unit. After the Loader Unit has finished loading the balls into the container on the train, the train leaves the Through Unit. In this way, the Through Unit enables a train to stay on the track for a while and to drive some component attached to the Through Unit.

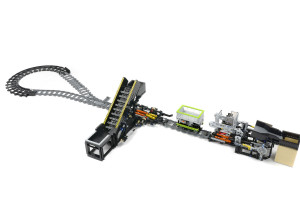

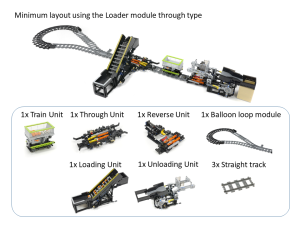

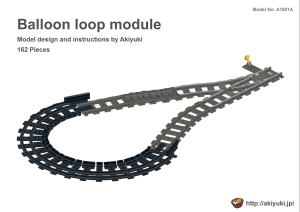

The following photographs show the minimum layout using the Loader module through type. The track of the layout includes a Balloon loop module. Usual rail parts are too large to construct the Balloon loop module, so narrower rail parts are used to make it smaller in size. The layout can be modified to put the Loading Unit inside the Balloon loop module.

I explain the mechanisms of the Through Unit as follows. When a train enters the Unit from the left, the train touches a stopper on the Unit. Then, the train stops and drives an attached Unit (in this case, a Loading Unit). A given amount of gear rotations releases the stopper, and the train starts to leave the Through Unit. When the train enters the Through Unit from the right, the train does not touch the stopper and goes through the Unit.

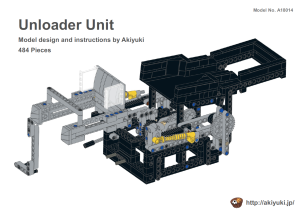

Components of the minimum layout using the Loader module through type:

Instructions and MPD files for the components of the minimum layout using the Loader module, through type:

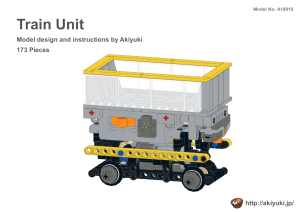

A18010_TrainUnit Instruction [PDF]

A18010_TrainUnit [MPD]

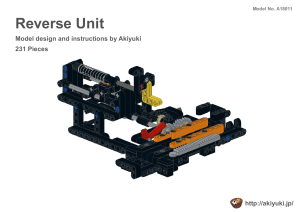

A18011_TrainReverseUnit Instruction [PDF]

A18011_TrainReverseUnit [MPD]

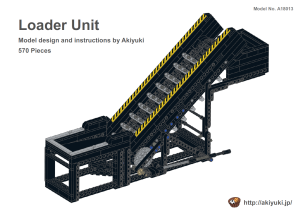

A18013_TrainLoaderUnit Instruction [PDF]

A18013_TrainLoaderUnit [MPD]

A18014_TrainUnloaderUnit Instruction [PDF]

A18014_TrainUnloader [MPD]

A18012_TrainThroughUnit Instruction [PDF]

A18012_TrainThroughUnit [MPD]

A1801A_TrainBalloonLoop Instruction [PDF]

A1801A_TrainBalloonLoop [MPD]

2018/7/16 MPD files were added.